HW’ROTATORS – Touchless Wash

The PROGRESS truck and bus wash machine is available in 4 different heights, 2 widths and flexible bay length, to adapt to the specific needs of your fleet. Vehicle types include; vans, trucks, trailers, buses, coaches and special vehicles such as tankers or public services.

With a hot-dip galvanised structure, its vertical brushes apply an overlapping front and rear scrub; it also offers great program flexibility depending on the type of fleet and number of vehicles being washed per day.

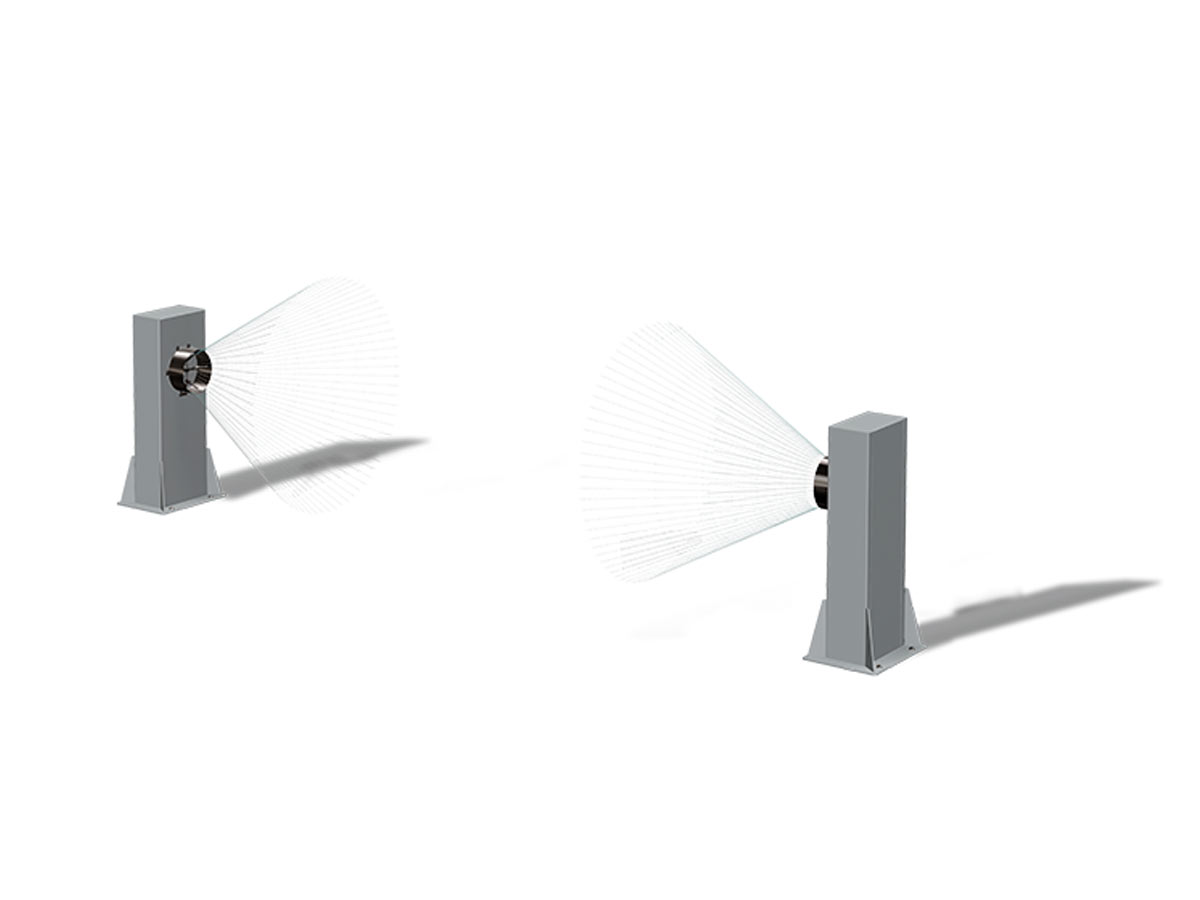

HW’ROTATORS – Burdett’s, Melbourne, VIC

Burdett’s chose to use this motorised rotators system to wash their trucks moving through the sand quarries in Melbourne. This high-pressure wash equipment is especially intended for the drive-through washing of all commercial vehicle types that cannot be washed with a standard rollover, as is the case of Burdett’s trucks.