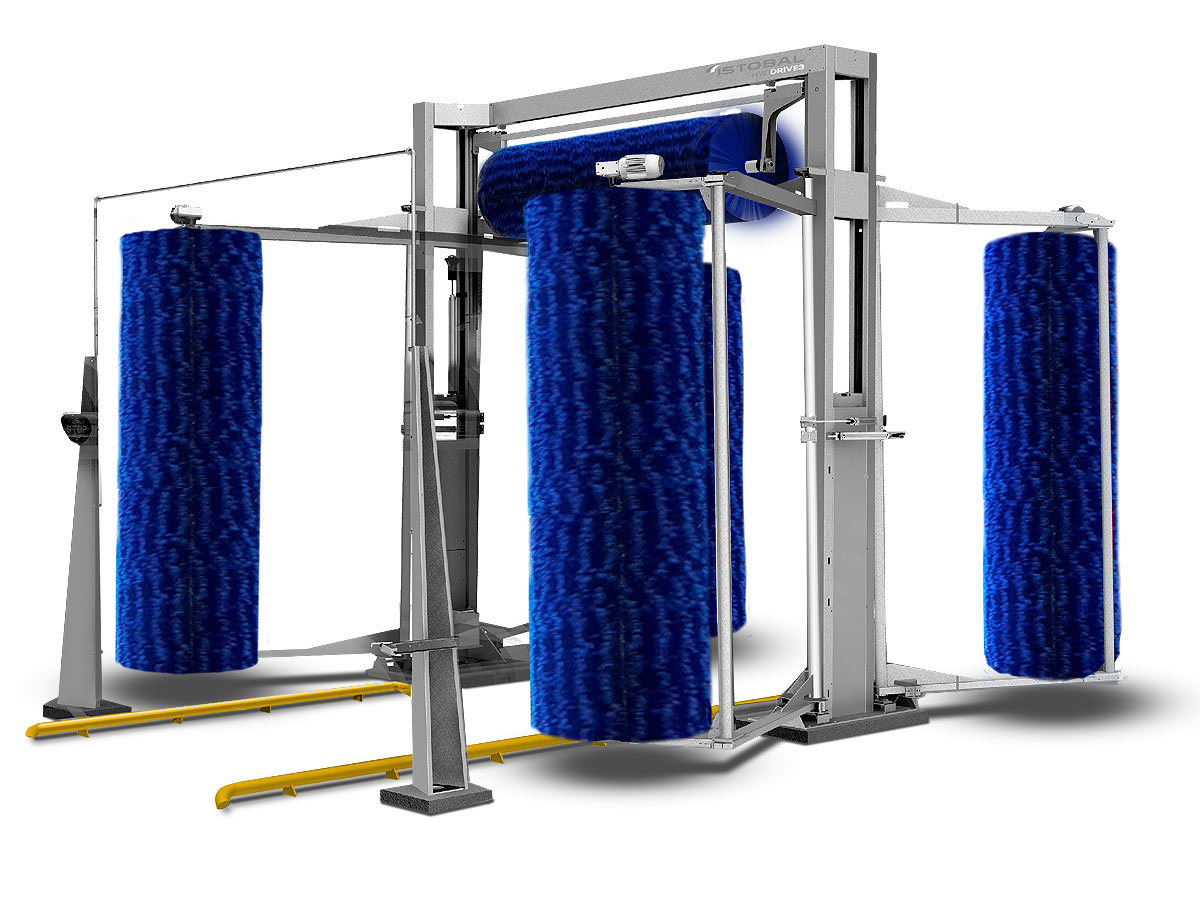

HW’DRIVE2 – drive through tram wash 4HWD200

This model includes a pre-soak arch, two rinsing arches, a displaced technical board with a touch screen, soft starters for its four brushes, and speed detection to avoid vehicle impacts. Until now it was unachievable to reach spectacular results in drive though tram wash.

Thanks to three pairs of photocells, the system detects if the vehicle reaches the speed limit. If this is the case, the front brushes are automatically opened before the vehicle reaches them, or the machine stops and stays in emergency mode.

optional extras

- Exit traffic light to indicate rear wash.

- Wax dosing.

- Integrated underchassis wash, 20 bar [290Psi].

- Demineralising unit.

- Recycling unit.

- esens® chemical products.

Front & Rear Wash

- Tilting brushes for trams: top part with pneumatic tilting enabled by cylinders, and bottom part with fixed tilt.

- Rotary joint between brushes for greater stability.

- System for more adaptability to the shape of the vehicles and for greater efficiency with trams.

Side Wash

- Upper vertical brush with minimum tilt to scan tram sides.

- 1/2 and 3/4 brushes spin in opposite directions for a better finish

- Soft starters for the 8 motors. Tangential tilting prevents brushes from moving into the interconnections between coaches.

- Cylinder system: Brush arms with limit switches.

- Cylinder control by wash zones: Front, side, back.

Touch Screen

- Control panel with touch screen model KTP400 by Siemens, installed on the door of the electrical cabinet, next to the emergency stop button. The touch screen allows users to carry out all control, configuration and maintenance tasks in a user-friendly way.

- Possibility of sending emails and optional screen access to control the facility remotely.

Optional Extras

- Exit traffic light to indicate rear wash.

- Wax dosing.

- Integrated under-chassis wash, 20 bar [290Psi].

- Demineralising unit.

- Recycling unit.

- esens® chemical products.

HW’DRIVE2

TBA….

Heavy Vehicle Range

Heavy Vehicle Range