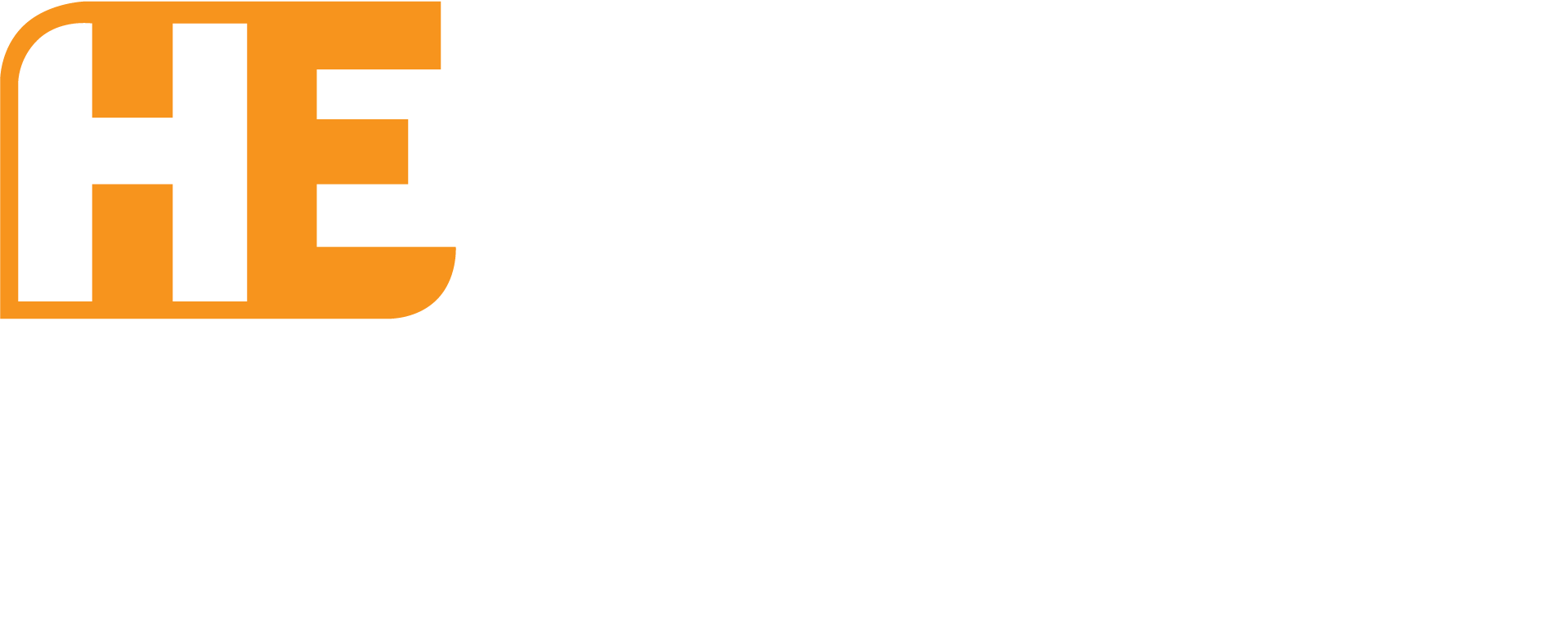

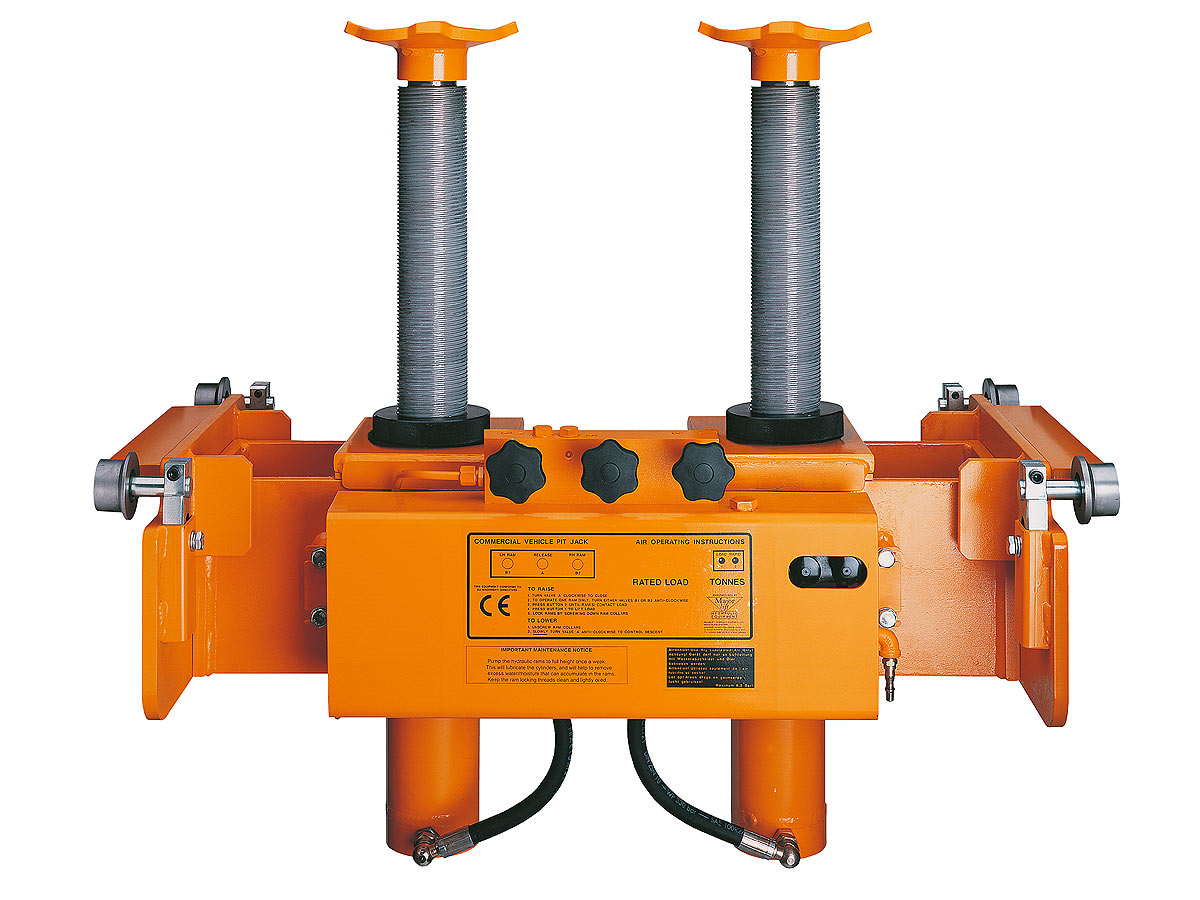

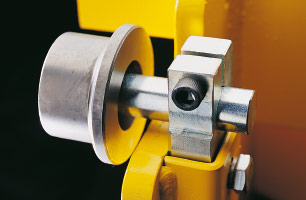

Surface engineered for a longer, harder working life

All key components in a Majorlift jack now have their working life greatly extended through a patented surface engineering process. This range of treatments develop iron nitrite surface compound layers to toughen the surface and resist rust. The nitrogen-enriched zone can improve yield and fatigue strengths by as much as three or fourfold.