Roller brake testers for trucks, buses & heavy vehicles

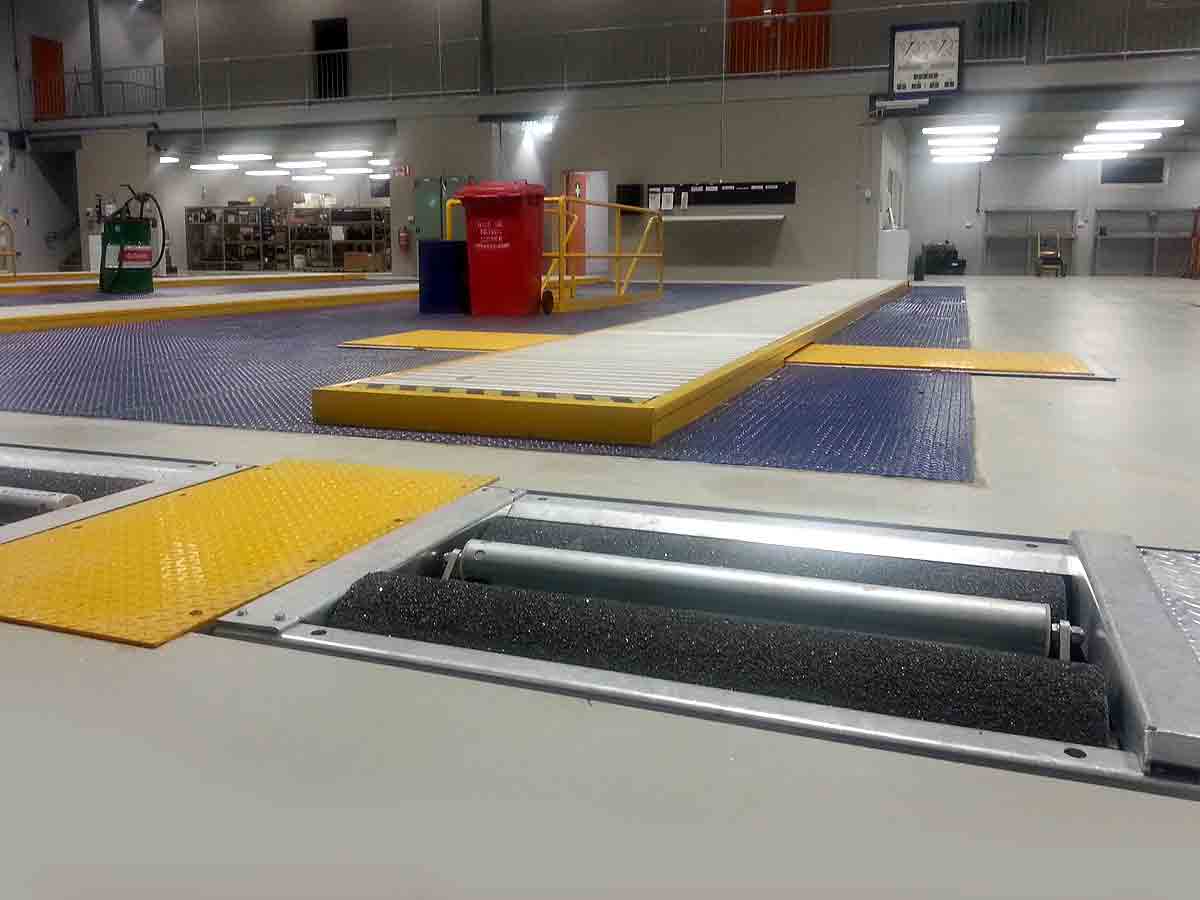

The VLT series of Roller Brake Testers for Heavy Vehicles come with level rollers to allow bi-directional testing as the pit is so short. It has a separate relay box with electric components.

Readout cabinet, 800 x 1000 mm, with 2 large digitally controlled analogue pointers, bright coloured indicator lamps and an alphanumeric LED display or 32” TFT monitor. It also comes with a Radio frequency remote control unit to control every function of the Roller Brake Tester.

Roller Brake Tester – VLT 16233

Like many transport companies, owner of Parry Logistics, Craig Parry approached Hartex to design and construct a truck service pit that could also serve as a Roads and Maritime services (RMS/RTA) inspection pit, fully fitted out with the latest in suspension testers (shakers) and roller brake testers.

Heavy Vehicle Range

Heavy Vehicle Range