Truck & Bus Emission Testers

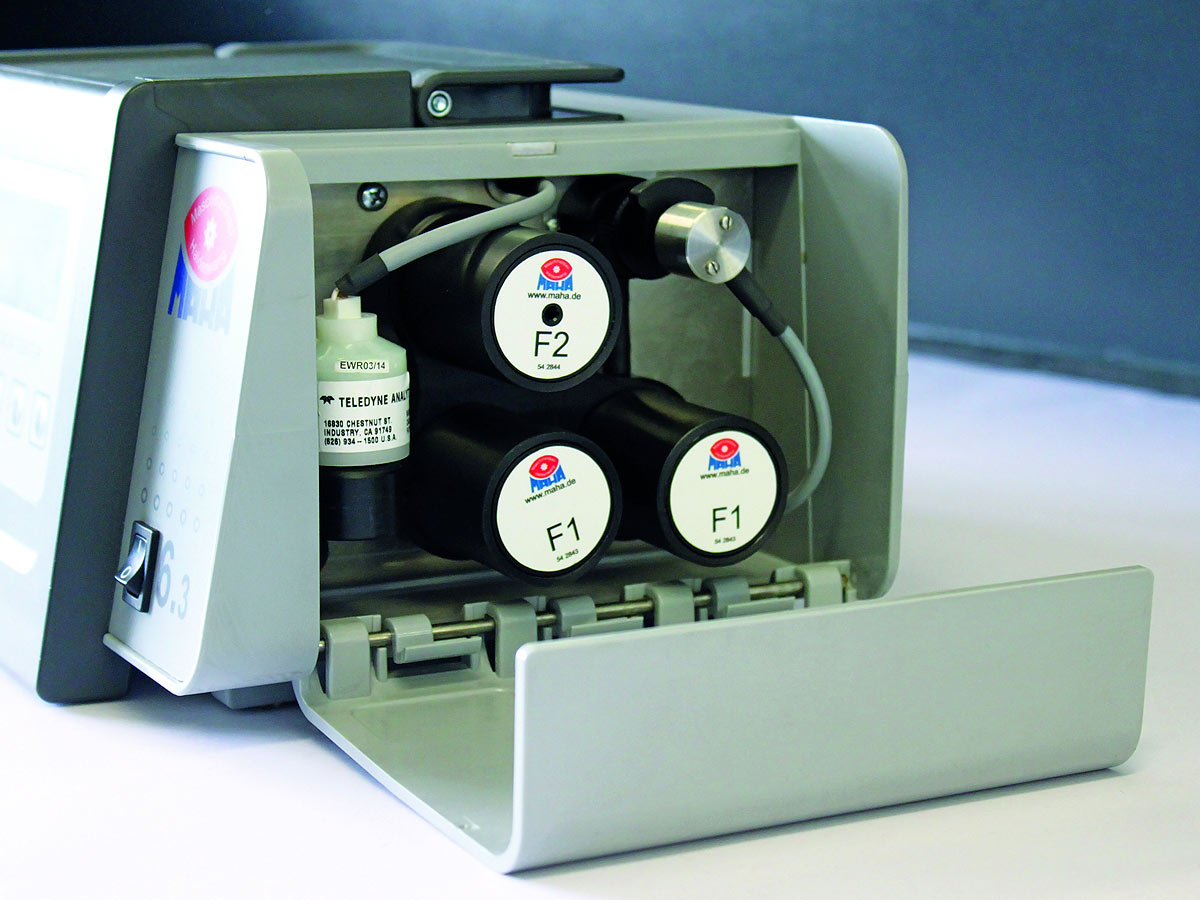

The MET 6.3 combination emission tester combines cutting-edge petrol and diesel emission measuring technology in one compact housing. The unique design offers the user extensive options for emission diagnostics, in addition to using the tester in the official exhaust emission inspection (AU). When the tester is fully equipped, it can simultaneously measure HC, CO, CO2, O2, NO, NO2, NOx, turbidity coefficient and particle mass concentration.

With its PC-supported inspection workflow, which is well-organised and user-friendly, it is the perfect emission tester for the legally prescribed AU emission inspection.

Thanks to its compact dimensions, low weight, wireless PC connection (optional) and OBD module, the MET 6.3 is particularly suitable for mobile applications. The optional heated 5.5 m probe hose for petrol and diesel measurement makes it easy to connect the emission probe to the vehicle being tested (e.g. to a lorry’s vertical exhaust pipe).

The MET 6.3 is backed up by a well-planned servicing scheme. When consumables (filters, O2 sensors, etc.) need to be changed, the software displays the component change that is due in good time. Highly durable consumable parts and service hatches that are straightforward to access reduce the effort required for servicing work to a minimum.

Petrol Tester Model

- Partial flow emission tester with display (basic unit) for the analysis of gas components HC, CO, CO2, O2 with Lambda calculation

- LAN interface (RJ 45)

- Innovative condensate separation

- Suitable for CNG-, LPG- and petrol-powered engines

- Option to Expand for NOx analysis (on request)

Diesel Tester Model

- Official German PTB-approval 18.09

- Partial flow diesel emission tester with display (basic unit) for the measurement of the opacity/particle concentration

- Time-saving, user-friendly emission testing with free acceleration or engine under load

- Instantaneous or continuous measurement

- LAN interface (RJ 45)

- Innovative condensate separation

Interface Options

- RS 232 interface

- W-LAN interface

MET 6.3 Emissions Tester

Thanks to its compact dimensions, low weight, wireless PC connection (optional) and OBD module, the MET 6.3 is particularly suitable for mobile applications. The optional heated 5.5 m probe hose for petrol and diesel measurement makes it easy to connect the emission probe to the vehicle being tested (e.g. to a lorry’s vertical exhaust pipe)